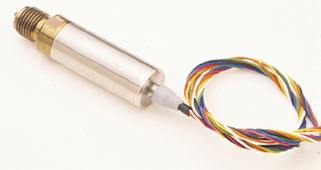

imagem meramente ilustrativa

Descrição

OMEGA’s PX3400 Series Pressure Transducer has earned a reputation for high performance, reliability and stability in tough, real-world applications. The PX3400 Series is particularly useful in deep well tools. It has a narrow body diameter of 0.75" (19mm) and pressure ranges up to 20,000 psi (1,400 bar). Two models are available, PX3425 operates up to 121°C (250°F) and the high temperature PX3435 which operates up to 177°C (+350°F). This outstanding transducer use OMEGA’s advanced sputtered thin-film sensor technology. Thousands of the PX3400 Series transducers are used for oil well logging throughout the world. Stability is critical. A transducer that shifts during a logging cycle invalidates costly data. The OMEGA’s PX3400 Series transducer uses thin-film strain gages, sputter deposited on a metal diaphragm. This advanced-technology gage system provides superior stability, especially at high temperatures often found in oil wells. The diaphragm is machined from vacuum remelted 17-4 PH stainless steel with elaborate annealing, aging and stress relieving processes to insure a stable system. The gaged diaphragm design minimizes the number of components and welds in the transducer, increasing the reliability and precision of your logging data. The heat sink effect of the diaphragm, and the high bridge resistance reduce gage self-heating, decrease warm up time and conserve battery power. A built in Platinum resistance temperature element (RTD) provides data to correct temperature effects with an external microprocessor. OMEGA’s PX3400 series transducer can be modified to meet your design requirements. A broad selection of optional features are available, including pressure and electrical connections, special testing, additional thermal compensation and 200°C (400°F) operating temperatures.

SPECIFICATIONS:

@ 25°C ±1°C

Excitation: 10 Vdc

Full Scale Output:

30 mV typical, 26mV minimum

Zero Balance: 0.0mV, +3 mV, -0 mV

Input & Output Resistance: 2000 Ω

minimum, 3000 Ω maximum

Insulation Resistance: 500 megohms

minimum @ 45 Vdc between any

connection and case over the calibrated

temperature range

Sensing Element: 4 active-arm bridge

Gages are sputtered-deposited on the

pressure summing diaphragm

Linearity: ±0.15% FSO maximum

measured best fit straight line through

all data points

Hysteresis: ±0.06% FSO (max) at

constant temperature for a complete

pressure cycle

Long Term Stability: Zero and

sensitivity stability is better than ±0.1%

over a six month period when the

transducer is operated within the

specified environment

Operating Temp Range:

PX3425: -54° to +121°C

(-65° to +250°F)

PX3435: -54° to +177°C

(-65° to +350°F)

Compensated Temp Range:

PX3425: -18° to +121°C (0° to +250°F)

PX3435: -18° to +177°C (0° to +350°F)

Thermal Effects:

(Over the compensated range)

Span: ±0.03% FSO/°F

Zero: ±0.03% FSO/°F

Vibration Sensitivity: At 35g peak

sinusoidal vibration from 10 Hz to 2000

Hz (1/2 ” D.A.) , the output shall not

exceed 0.003% FSO/g

Natural Frequency: >50,000 Hz

Shock: Qualification level of 100g,

11 msec half sine wave without damage

Temperature: Platinum resistance

device to DIN43760 (alpha = 0.00385

½/ohm/°C). See ordering box for

resistance at 0°C (32°F)

Proof Pressure: 1.5 times rated

pressure or 25,000 psi whichever is

less, will not cause the performance to

shift beyond the specified tolerances

Burst Pressure: 2.0 times rated

pressure or 30,000 psi whichever is

less, will not cause rupture of the

pressure containment cavity.

Wetted Parts: 17-4 PH Stainless Steel

Electrical Connection:

7 separate PTFE insulated stranded

wires 25" ± 2" (0.6m ± 0.05m) in length

Pressure Fitting:

9/16 -18 UNF-2A (Mates

with Autoclave F250C or Sno-Trik 44F)

Weight:

4 oz (114g) max including cable

Calibration Record:

OMEGA’s Calibration record is supplied.

Also documented is the pre-ship output

at atmospheric pressure and the

temperature sensor resistance at

25°C ± 2.8°C (77°F ± 5°F)

Options: Special electrical and

pressure connections. Special testing

and calibration procedures. Higher

operating temperatures.