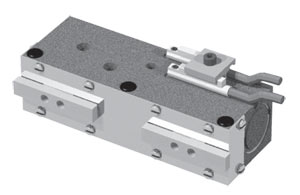

RPLC Series - Parallel Gripper with Clean Room Rating

parallel pneumatic grippers

imagem meramente ilustrativa

-

Precision Gripping - Preloaded V Roller Bearings Eliminate Side Play Resulting in Excellent Part Positioning

-

Class 10 Clean Room Rated with Corrosion Resistant Shield, Clean Room Grade Lubricant and Scavenge Port

-

Components Protected by Stainless Steel Shield for Use in Harsh Environments

-

Accuracy of 0.05 mm (0.002") and Repeatability of 0.03 mm (0.001")

-

Rigid and Low Friction Design Allows for Longer Finger lengths for Use on Delicate Parts

-

Non-Synchronous Motion Option Provides Independent Jaw Operation

-

Up to 5 Million Cycles in Typical Operation and 10 Million with Maintenance

-

Operating Temperature -35 to 80°C (-30 to 180°F)

-

System Requires 0.3 to 7 bar (5 to 100 psi) Dry Filtered (40 Micron or Better) Air Supply

-

Requires 4-Way, 2 Position Valve and Regulator for Delicate Parts

Movimento - Ver Produtos Relacionados

Descrição

This product has been discontinued.

RPLC Series Gripper is a pneumatic parallel gripper with excellent parallelism and accuracy between the gripper mounting surface and jaw surface. Jaws are front mounted and are supported with 'Dual-V" roller bearings to provide low friction motion and are preloaded for maximum support and zero side play. This gripper supports longer finger length designs compared to other grippers of similar sizes. These grippers are available in stroke lengths from 6.4 to 19.1mm (0.25 to 0.75") with a grip force from 116 to 160 N (26 to 36 lbs).

RPLC gripper are Clean Room and Harsh Environment rated with a corrosion resistant shield to protect the drive and bearing mechanism from chips and other contaminants. All internal components are lubricated with clean room grade lubricant and the scavenger port can be used with vacuum to prevent escapement of particulate. It can also be used with pressure to repel particulate away from the jaws. This gripper is designed for class 10 clean room, FDA, and medical applications.

Linear motion pneumatic components are double acting cylinders that require a dry air supply with filtering to 40 microns or better. For best control of pneumatic components, flow control valves (regulating out) should be installed to regulate the speed of the device. Position sensors can easily be added to motion components to detect the end of travel positions of the slides, they are the standard method of communication with the PLC and are available in inductive or magneto resistive sensing styles and come in both PNP or NPN sourcing signals.

TECHNICAL SPECIFICATIONS

Pneumatic Specifications

Pressure Operating Range: 0.3 to 7 bar(5 to 100 psi)

Cylinder Type: Dual double acting

Dynamic Seals: Internally lubricated Buna-N

Valve Required to Operate: 4-way, 2-position

Air Quality Requirements

Air Filtration: 40 micron or better

Air Lubrication: Not necessary*

Air Humidity: Low moisture content (dry)

Temperature Operating Range

Buna-N Seals (Standard): -35 to 80°C(-30 to 180°F)

FKMSeals (Optional): -30 to 120°C(-20 to 250°F)

Maintenance Specifications

Expected Life:

Normal Application: 5 million cycles

With Preventative Maintenance: 10+ million cycles*

Field Repairable: Yes

Seal Repair Kits Available: Yes

*Addition of lubrication will greatly increase service life.